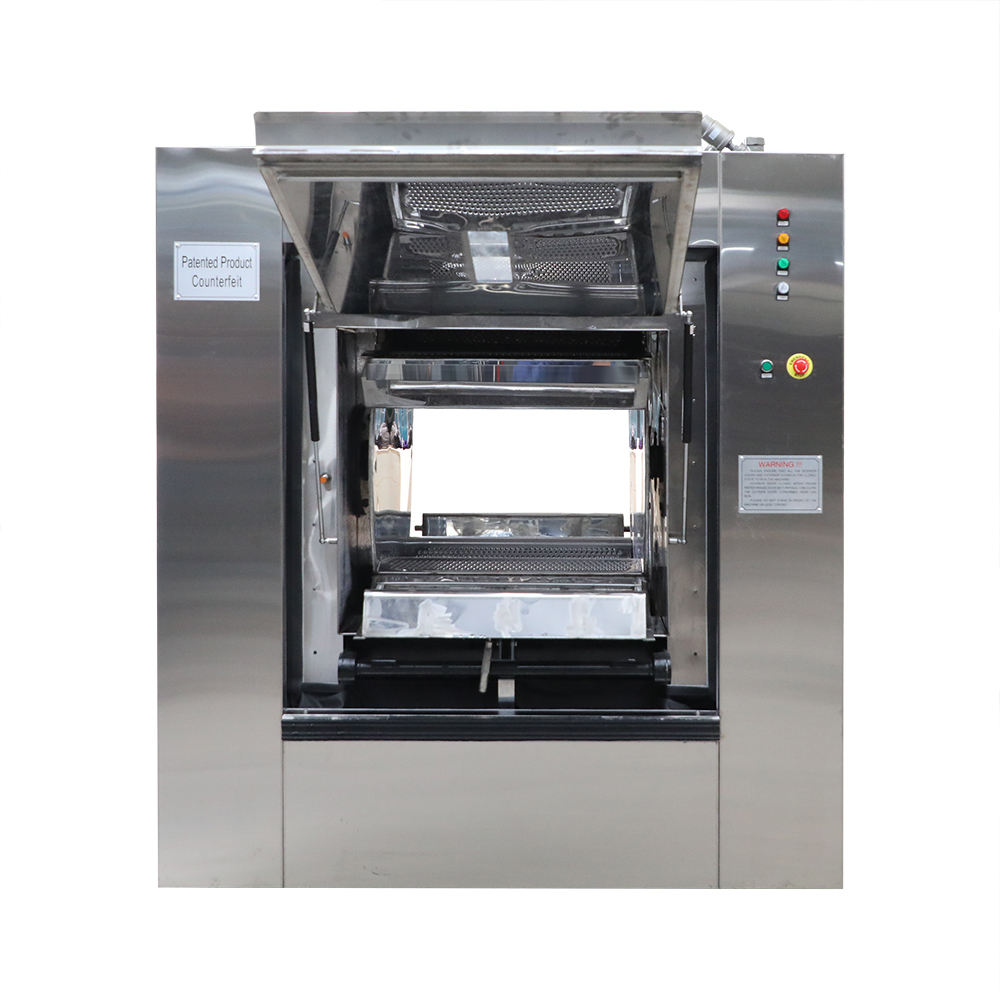

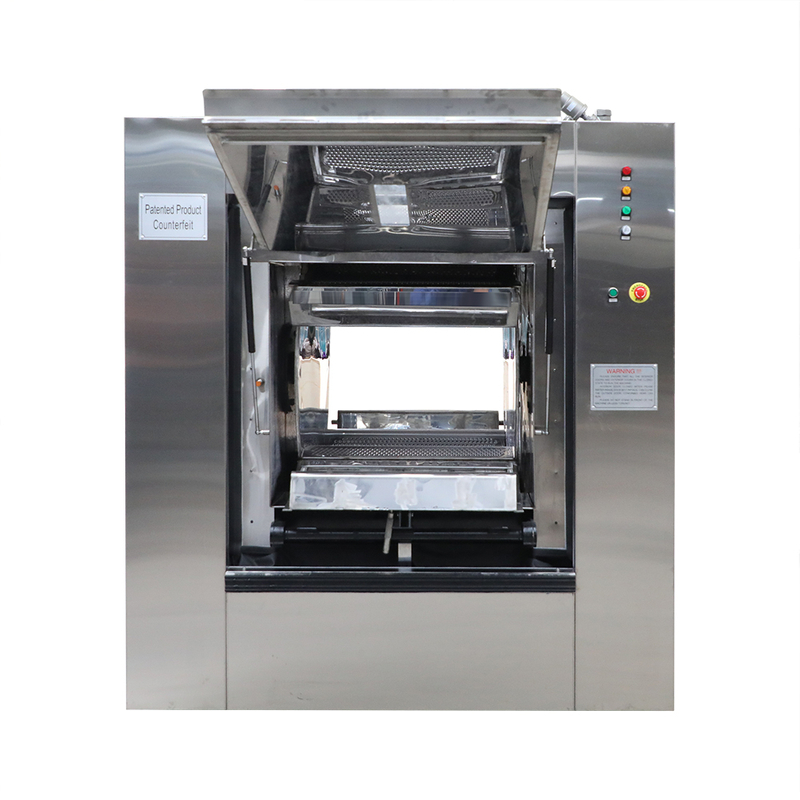

Clean Room Glove Barrier Washer Extractor Machine 100kgs

Features and Benefits:

1. Barrier wall two doors design separate loading at non-clean room side and unloading at clean room side ensure high quality clean room gloves up to class 10 standard

2. Special designed inner drum to protect gloves and prevent gloves slipping out

3.Parts in contact with water made of high grade stainless steel 316L withstand RO, DI or EDI water

3. Trouble-free Industrial designed shaft and bearing design with strong casted bearing housing

4. Air bags suspension system offer high-spin extraction retain minimal water in the gloves for quick drying process subsequently without additional hydro-extractor, saving time and energy

5. Compact design with large diameter drum, saving installation space and also give better agitating effect for better cleaning process

6. Separated compartment with automatic positioning feature for safe and easy unloading in a slope position at ergonomic height, saving time and reduce labor fatigue

7. Tight-seal door allow water filling above drum half-line, maximize water filled in contact with gloves with better soaking effect, maintain clean and tidy working environment

8. Minimum non-effective space between inner drum and outer drum save water usage with same result

9. Fully programmable touch screen computer up to 99 programs allow maximum flexibility to adjust and achieve best possible result for different process requirement in automatic mode

10. Standard two large water inlet valves and one drain valve with possibility to add more valves meeting different process requirement

11. Water sampling valve to collect water for testing and inspection ensure consistent batch process quality

12. Water reuse capability with external filtration system

13. Built-in weighing scale to check and manage production load

14. Internet connectivity for rerote management control and monitoring

Model | BW20 | BW30 | BW50 | BW100 |

Maximum Capacity kg | 20 | 30 | 50 | 100 |

Inner Drum D×L mm | Φ730×490 | Φ900× 500 | φ970×720 | Φ 1200×890 |

Motor Power kw | 2.2 | 4 | 5.5 | 11 |

Washing Speed rpm | 35 | 35 | 35 | 32 |

Rotation rpm | 70 | 70 | 70 | 65 |

Extracting Rotation rpm | 440 | 400 | 370 | 350 |

Fast Speed Rotation rpm | 920 | 800 | 750 | 750 |

Steam Inlet mm | DN20 | DN20 | DN20 | DN25 |

Water Inlet mm | DN40 | DN40 | DN40 | DN50 |

Drain mm | Φ89 | Φ89 | Φ89 | Φ 140 |

Water Pressure Mpa | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

Steam Pressure Mpa | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

Air compressor Mpa | 0.4-0.5 | 0.4-0.56 | 0.4-0.5 | 0.4-0.5 |

Water Consumption kg | 300 | 450 | 700 | 1650 |

Steam Consumption kg | 15 | 25 | 45 | 50 |

Electricity Heating Power Kw | 18 | 24 | 36 | 48 |

Overall Dimension (Front Back) mm | 1250 (1300) | 1400 (1450) | 1500 (1550) | 1720 (1770) |

Overall Dimension (Left Right) mm | 1360 (1440) | 1370 (1450) | 1640 (1720) | 1810 (1890) |

Overall Dimension (Height) mm | 1690 (1840) | 1800 (1950) | 1880 (2030) | 2150 (2300) |

Weight kg | 800 | 1140 | 2000 | 3000 |

Power Supply V/Pn/Hz | 380/3/50 | 380/3/50 | 380/3/50 | 380/3/50 |