Hospital linens require a higher standard of cleanliness compared to hotel linens due to stringent hygiene requirements. Stains on medical fabrics must be thoroughly removed, and rinsing and disinfection must be comprehensive. However, the fabric quality of medical textiles varies, so how can laundry plants improve the hygiene standards of hospital linens? This article will delve into what constitutes a standardized washing process and how to enhance the hygiene standards of hospital linens.

I. Standardized Washing Process

It's well-known that the quality of linen washing is influenced by various factors, such as the quality of industrial washer extractor, the quality of detergents, water quality, washing temperature, washing time, and other human factors. Feedback from consumers and staff indicates issues such as linen turning yellow, gray, or becoming stiff after washing. Analysis by industry experts reveals that the main reason for these issues is problems with the washing process, such as the lack of pre-washing of stains on the linen, absence of water softening, or excessive temperature during drying.

With the advancement of technology, the automation level in the washing industry has greatly increased. Industrial washing machines have replaced manual washing, and staff only need to sort the linen, add detergents, and adjust washing time and temperature to complete the washing process. In this working mode, how can we improve the cleanliness of linen? Standardized washing processes become the key to solving this problem. While we can control the composition of washing chemicals and water quality from the source, standardized washing processes must be established for the remaining washing steps.

After continuous exploration and practice, laundry plants have established the following standardized washing process: pre-wash - main wash - rinse - water exchange - acid neutralization.

Let's explain the washing process step by step:

Pre-wash:

Pre-wash involves rinsing the linen with clean water in an industrial washing machine to wet the fabric and remove some water-soluble dirt through the combined action of water impact and repeated rubbing and beating of the industrial washing machine. This process may seem ineffective for washing linen, but it's essential. Pre-washing prepares the linen for the main wash, improving washing effectiveness and reducing detergent usage. Skipping this step and proceeding directly to the main wash can lead to certain stains, which are originally easy to remove, becoming stubborn stains under the high temperature of the main wash. Therefore, regardless of how good the washing conditions are, after sorting the linen, pre-washing must be carried out.

Main wash:

The main wash is a critical process in the water washing of linen. After pre-washing, the water is drained, and then water is added to the medium level. Finally, according to the condition of the linen, cleaning agents are added and the water temperature is adjusted. Generally, the washing temperature for hotel bathrobes is around 80 degrees Celsius, and for bed sheets and towels, it's around 90 degrees Celsius. Through the main wash, the chemical action and speed of the detergent with dirt can be increased, achieving disinfection and sterilization.

Rinse:

Rinsing involves bleaching treatment. Although most dirt is removed after the main wash, some stubborn stains may still remain. Therefore, bleaching treatment is required. As the name suggests, rinsing is disinfection with bleach, which is usually divided into chlorine bleaching and oxygen bleaching. Oxygen bleaching is less likely to fade, and it has less damage to linen. The time is approximately 12 minutes, and the temperature is around 80 degrees Celsius. Chlorine bleaching has excellent bleaching properties, but it is prone to discoloration, and it causes significant damage to linen. The time is approximately 8 minutes. Therefore, it's necessary to choose the appropriate bleaching method according to the type of fabric, which can greatly improve the quality of fabric washing.

Water exchange:

After the main wash and bleaching, the linen generally undergoes a medium or high-speed dehydration process to reduce the residual washing liquid in the fabric. During this process, controlling the water level is crucial for washing quality. Excessive water will cause a decrease in chemical concentration and an increase in steam usage, resulting in incomplete cleaning of linen and wastage of steam. Therefore, after heating, the water level in the industrial washer must be controlled at a low level. The lower the water level, the lower the cost, the higher the efficiency, and the better the quality.

Acid neutralization:

The detergents used in washing are usually alkaline. Although repeated rinsing may not completely remove all alkaline components, the presence of alkaline substances can affect the appearance and feel of the washed fabric and may even have adverse effects on the skin and health. Therefore, after rinsing, acid neutralization is required to adjust the pH value of textiles to be closer to human skin, typically controlled at around pH 6.3.

II. How to Improve the Hygiene Standards of Hospital Linens

1. Implementing Full Process Quality Management for Medical Textile Washing and Disinfection

Implementing full-process quality management means implementing quality control in all aspects of medical textile receiving and delivery, washing, disinfection, sorting, transportation, etc.

Ensure clean and soiled items are separated during receiving and delivery, with no cross-contamination, and employ closed-loop receiving and delivery.

During sorting, carefully inspect soiled textiles, promptly remove debris, classify and label, and tightly package infectious linens to prevent secondary contamination.

During washing and disinfection, strictly follow the pre-wash, main wash, rinse, and neutralization sequence, avoid mixing different types of textiles, control water quantity and temperature, add appropriate amounts of detergents and disinfectants, monitor washing and disinfection times, and pay attention to disinfection indicators and pH values to ensure thorough removal of dirt and meet disinfection requirements.

For drying, ironing, and finishing, ensure thorough drying, store clean textiles in bags to prevent secondary contamination.

The design, installation, and ventilation of laundry rooms should take measures to minimize microbial contamination, with sufficient airflow, filtration devices, exchange rates, and exhaust volumes.

Rooms for storing soiled and clean textiles must be separated, with airflow from clean to contaminated areas being preferable. Clean textile storage rooms should be ventilated and dry, with storage racks positioned more than 20 cm above the ground, more than 5 cm from the walls, and more than 50 cm from the ceiling. Storage racks and transport vehicles should be regularly cleaned and disinfected with disinfectants.

Textile transportation should use closed vehicles, with contaminated and clean textiles not mixed, and vehicles should be disinfected promptly.

2. Choose Laundry Plants with High Hygiene Conditions

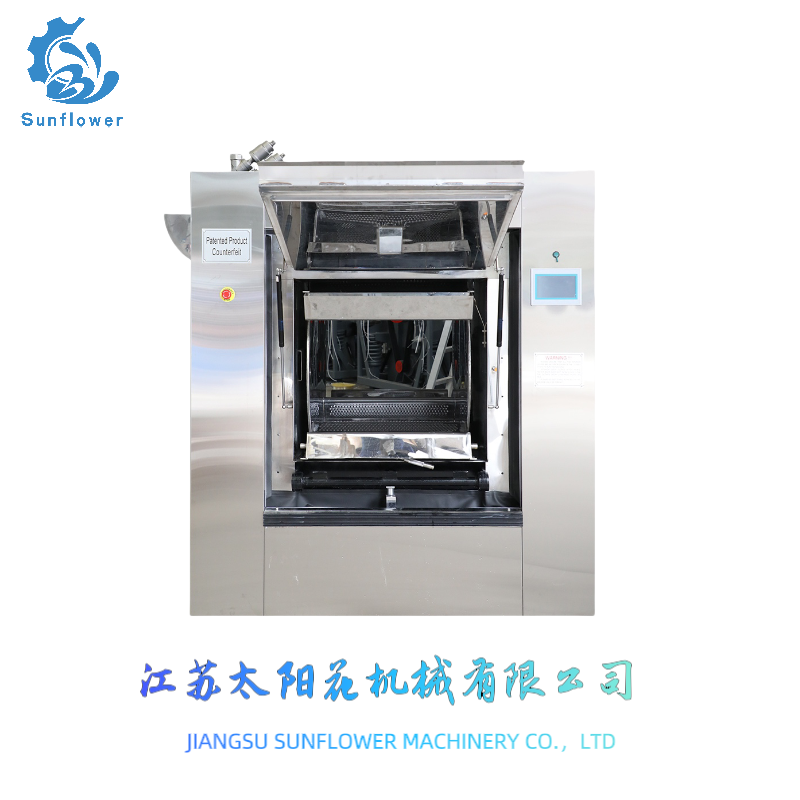

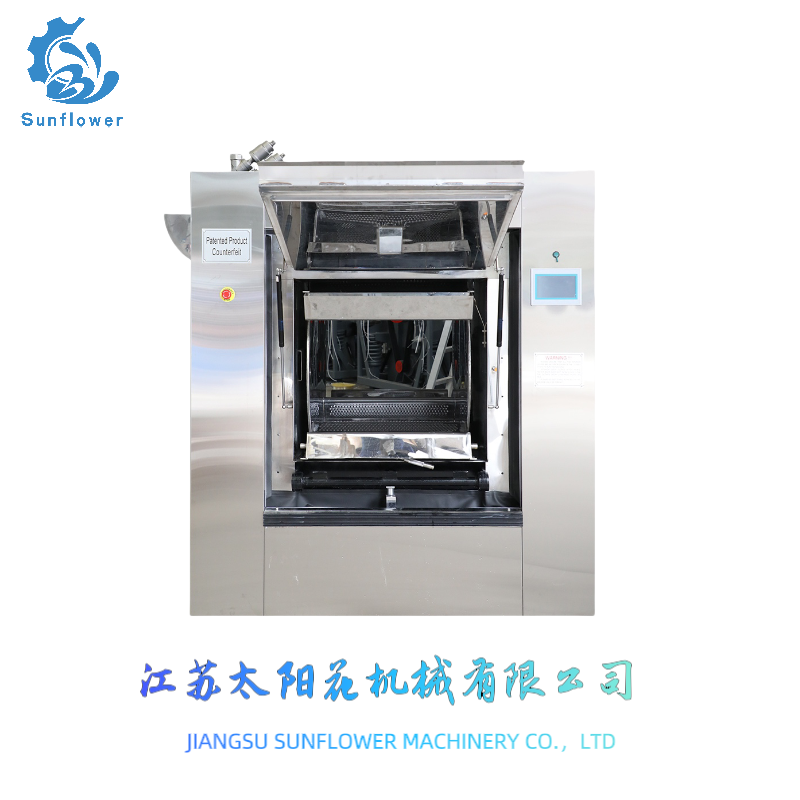

Laundry plants' infrastructure and washing equipment should meet the high standards of hospital washing requirements. For example, laundry plants need to have high-hygiene-standard washing machinery such as isolation washing machines to control linen washing hygiene standards from the source.

3. Strengthen Training of Laundry Personnel's Business Knowledge

The quality of hospital textile washing and disinfection depends not only on the advancedness of washing and disinfection equipment but also on the knowledge level and business capabilities of staff. Strengthening professional training for staff and implementing scientific human resource management are essential to ensuring the quality of hospital linen washing and disinfection.

Jiangsu Sunflower Machinery Co., Ltd. is committed to producing supporting industrial washing equipment for the chemical industry, such as industrial washing machines, industrial dryers, industrial ironing machines, industrial folding machines

, etc., to provide customers with integrated green washing solutions. Our company is a source factory, controlling product quality from the source, and striving to bring high-quality, high-performance equipment to customers. In addition, our company is equipped with a professional technical team and after-sales team. If you have any problems after receiving the products, you can contact us at any time, and we will provide you with the most professional technical guidance and problem-solving.

Please feel free to contact us if you have any equipment needs!