A:Our company is located in No. 48 Factory Building, Hailing lndustrial Park, Hailing District, TaizhouCity, Jiangsu China. 2 Q:What washing equipment does your company mainly produce?

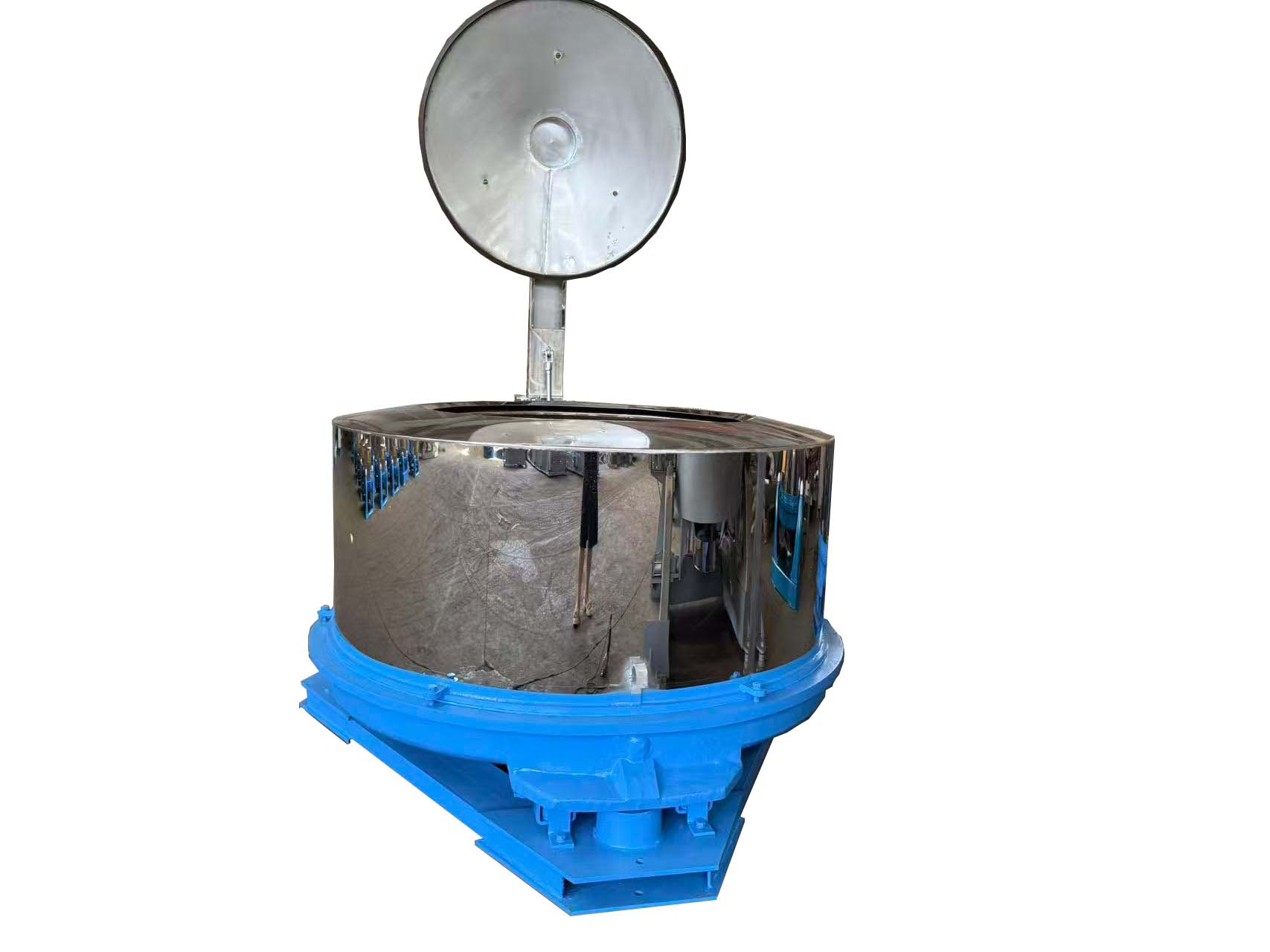

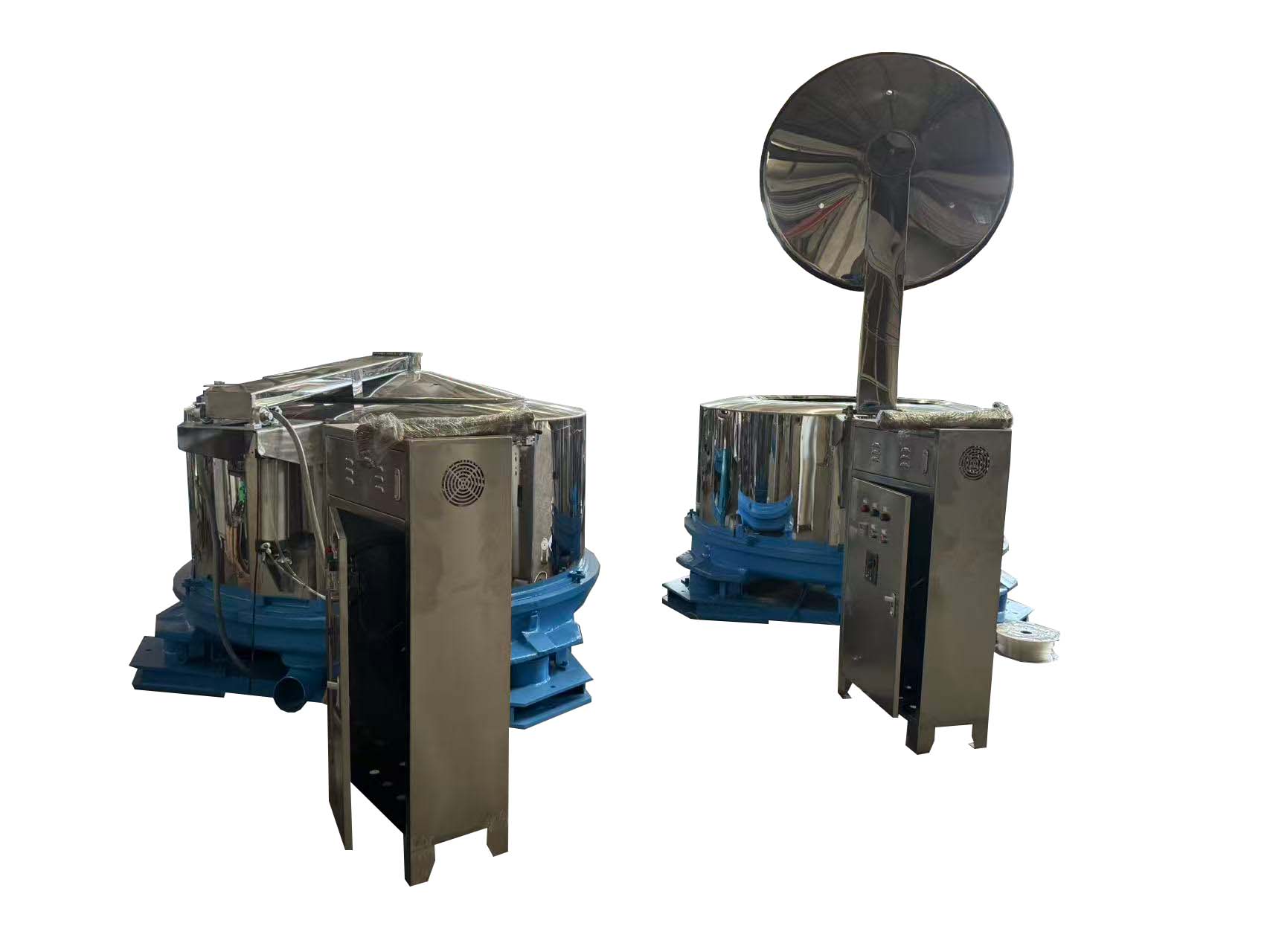

A:Our company mainly produces industrial Washers And Dryers, industrial lroning MachinesDewatering Machines, Folding Machines, lroning Machines, Steam Form Finishing Machines.Stackable Washer Dryer Machines, Garment Packaging Machines, etc.

3 Q:What industries is your equipment suitable for?

A:Our equipment can be used for dust-free washing in the pharmaceutical industry and dust-free workclothes washing in electronics factories. Garment factory washing, drying and dyeing of sweaters, jeans.gloves, plush toys. Washing, drying, ironing and folding of hotel and hospital bed sheets and quilts.Washing of rubber plastics and dehvdration of vegetables. etc. Our equipment is widely used in toursmcatering, clothing washing, leather manufacturing, and latex products industries.

4 Q:How is your company's after-sales service?

A:All equipment of our company will undergo strict quality inspection and test run before leaving thefactory. To ensure that customers can use the equipment normally after receiving it. After the customerreceives the equipment, our professional technical team will remotely guide the customer to install it. lfany technical guidance is needed during subsequent use, our engineers will provide help timely.

5 Q:How long does your company's delivery time take?

A:Our delivery time is generally about seven to fifteen days, and during peak season, the delivery timeis about twenty days.

6 Q:How long is the warranty for your products?

A:Our warranty is eighteen months to two years based on the date of the bill of lading, but we providelifelong service for the washing and drying equipment and ironing equipment we produce.

7 Q:Does your company provide pre-sales guidance?

A:We will recommend the equipment and quantity of equipment that suits you based on the actual siteconditions and daily workload.