100kgs Sweater Washing Dyeing Machine

Item | Name | Specification |

1 | Sweater Washing Dyeing Machine (Hot water +Cold Water ) | Vertical Type Front Loaded with one door Steam heated or Built In Electricity heater |

2 | Operation panel and Programs | Programable Operation panel with unlimited programs brand Pump |

3 | Rated Capacity (Wet )KG | 100kgs |

4 | Washing Drum , Inner dru and shell | Stainless steel SS304 |

5 | Shell Thickness | δ1.2 |

6 | Washing Chamber thickness | δ2.5 |

7 | Inner Drum thickness | Δ3.0 |

8 | Drum size DÍL mm | φ1200Í840 |

9 | Shock reducing system | Shock absrober and 4 spring |

10 | Motor | Ford Frequency motors 11 kw |

11 | Bearing | TWB 2224-22222 |

12 | Invert | Invert 15KW |

13 | Water consumption (kg/1 time wash hand 2 times bleaching ) | 900 |

14 | Steam consumption | 0.9kg/kg |

15 | Electricity consumption Kw.H | DN25—DN50 |

16 | Washing /Balancing speed rpm | 5KW (electricity heating power 40KW) |

17 | Middle/High extract speed | 30/60 |

18 | Steam port size and water inlet port size | 350/700 |

19 | Overall Dimension (WÍLÍHmm) | 1750*2000*2000 |

20 | Main power line | 4-25平方(3+1) |

21 | Weight | 2900KG |

Sweater Washing Dyeing Machine with programmable computer operating system , offering our customers with easy programming, and tremendous energy savings compared. Owners of this washer extractor will be impressed with the water savings they achieve and the benefits to their operation.

The easy-to-use controls and flexibility of the pre-programmed cycles will be a hit with customers.

They can add an extra wash, rinse or choose both to create a personalized wash cycle based on

their individual needs. Customers will appreciate the large LED display that leads the user through the washing process. .

1. Fully automatic, microcomputer-controlled.

2. High quality stainless steel, good appearance, long life.

3. Microprocessor, freely programmable, 5 standard programmers, 25 possible programmers.

4. Full suspension shock structure, suspension, combination of shock absorbers and springs for

maximum absorption, need no excessive foundations.

5. Imported bearing, precise and durable.

6. Fixed support for long-distance transportation, avoid shaking damage during transit.

7. High quality inverter system, easily realize washing and dehydration frequency steeples adjusting.

8. Built-out bearing lubrication, simple operation, and convenient maintenance.

9. Safety door interlock system. With sample door.

10, Multiple sealing system, oil sealing, water sealing, stainless steel sealing.

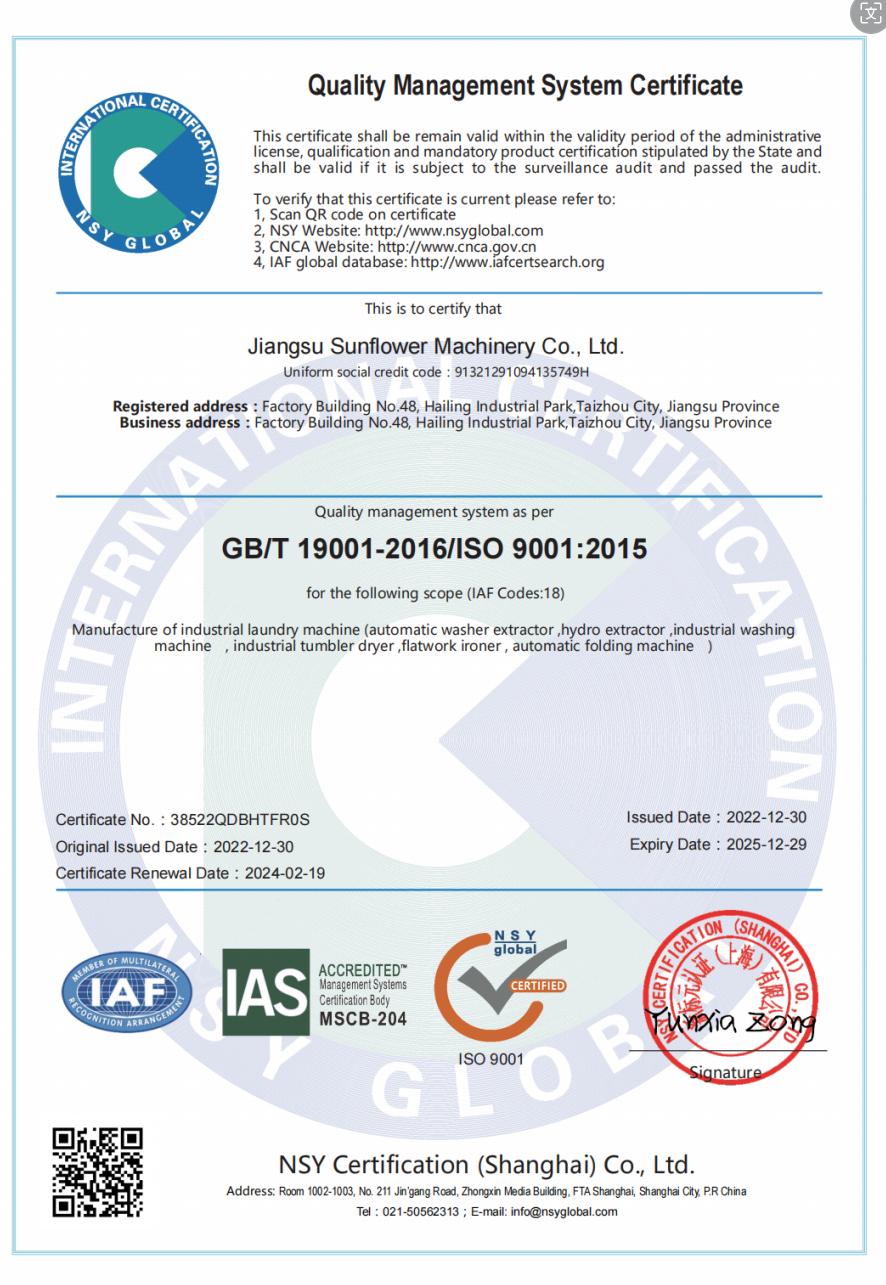

11. With CE and ISO9001 certificates.

Sweater dyeing machine is an industrial equipment specifically used for dyeing knitted sweaters (finished garments). It is different from equipment that dyes yarn or fabric, and its core feature is the ability to process sweaters that have already been woven and have a complete shape, while maximizing the protection of the sweater's pattern, texture, and feel during the dyeing process, preventing deformation, pilling, or damage.

ONE、 Sweater Washing Dyeing Machine working principle

Sweater dyeing machines typically operate by combining gentle mechanical action with precise temperature control systems

1. Dressing: Load the sweater to be dyed into the drum inside the machine.

2. Inlet water: Inject water and the required dyes and additives (such as leveling agents and softeners).

3. Circular staining:

Gentle mixing: The drum operates in a slow, intermittent forward and reverse rotation mode. This gentle mechanical action ensures that the dye can evenly penetrate every part of the sweater, while avoiding severe friction that can cause deformation or felting of the sweater.

Accurate temperature control: The control system precisely controls the heating, insulation, and cooling processes according to the preset process curve. This is crucial for dyeing different fibers such as wool, cashmere, cotton, and synthetic fibers.

4. Cleaning and dehydration: After dyeing is completed, discharge the residual liquid and rinse with water multiple times to remove floating colors. Many dyeing machines also integrate dehydration function, which removes excess moisture from sweaters through high-speed rotation, preparing for subsequent drying.

5. Outfit: After completing all the procedures, take out the dyed sweater.

Two、 Core Sweater Washing Dyeing Machineadvantages

1. Excellent shape protection: core advantage. By precise control of gentle mechanical movements, the sweater is effectively prevented from being stretched, shrunk, or twisted in a wet state, maintaining the original shape of the garment.

2. Excellent dyeing quality: Ensure uniform and full color, without any issues such as flowers or spots. Good permeability to complex knitted structures such as twists and ribs.

3. Wide fiber adaptability: By adjusting process parameters, it can be applied to wool, cashmere, cotton, acrylic, nylon, and various blended materials.

4. High automation and intelligence:

Computer control system: capable of storing hundreds of dyeing formulas, achieving fully automated operation and reducing human error.

Accurate temperature control system: ensuring color reproducibility for each batch of products.

5. Energy conservation and environmental protection:

Low Bath Ratio Design: Modern models adopt low bath ratio technology, which means using less water and chemicals, reducing the consumption of water, electricity, and steam, and reducing wastewater discharge.

Thermal energy recovery system: Some high-end models are equipped with thermal energy recovery devices to further reduce energy consumption.

6. Easy to operate and safe: The human-machine interface is user-friendly, with fault self diagnosis function and multiple safety protection devices (such as door locks, overheating protection, etc.).

Design of Knitted Sweater washing dyeing machine from Jiangsu Sunflower Machinery Co.,ltd will help you save Water ,Chemical, Labour and Time