Classification and standard of clean room

The development of dust-free workshops is closely linked with modern industry and cutting-edge technology. At present, it has been widely and maturely used in biopharmaceutical, medical and health, food daily chemical, electronic optics, energy, precision instruments and other industries. The dust-free workshop is divided into several grades, which are grade 1 ≥ grade 100 ≥ grade 1000 ≥ grade 10,000 ≥ grade 100,000 ≥ grade 1 million, the higher the rank, the higher the grade, and grade 1 is the highest. The most common ones are from 100 to 100,000 grades, and different grades have different grade standards.

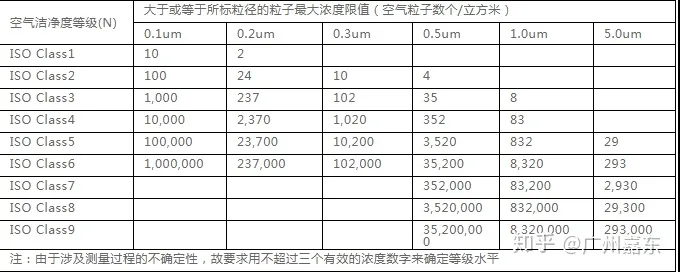

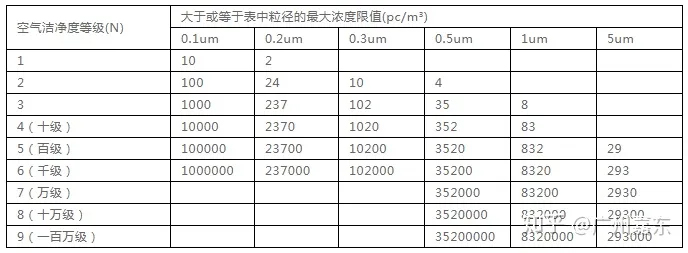

Air cleanliness level:

In the unit volume of air in the clean space, the grade standard is divided by the maximum concentration limit of particles greater than or equal to the considered particle size. In China, the dust-free workshop is tested and accepted according to empty state, static state and dynamic state, which conforms to "GB50073-2013 Clean Room Design Code" and "GB50591-2010 Clean Room Construction and Acceptance Code".

The cleanliness and the continuous stability of pollution control are the core standards for testing the quality of the clean room. The standard is divided into several grades according to factors such as the regional environment and cleanliness. Commonly used are international standards and domestic regional industry standards.

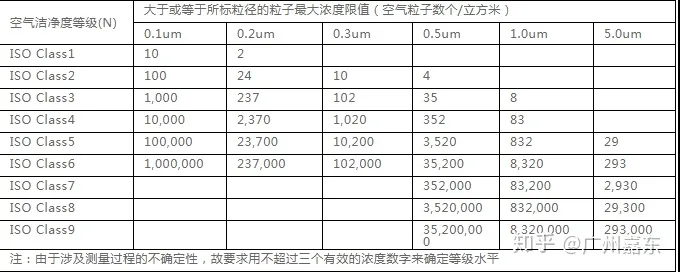

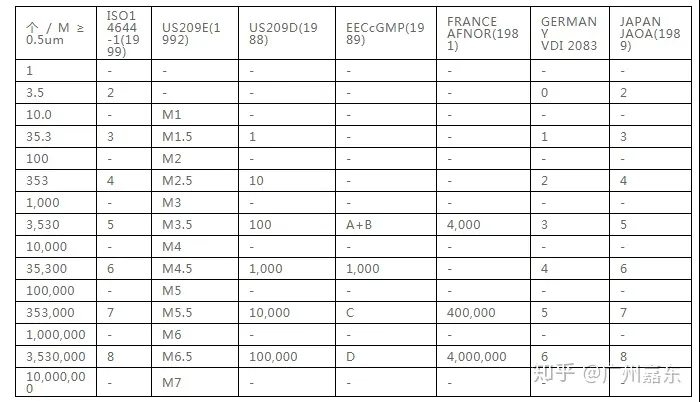

ISO14644-1 International Standard—Classification of Air Cleanliness

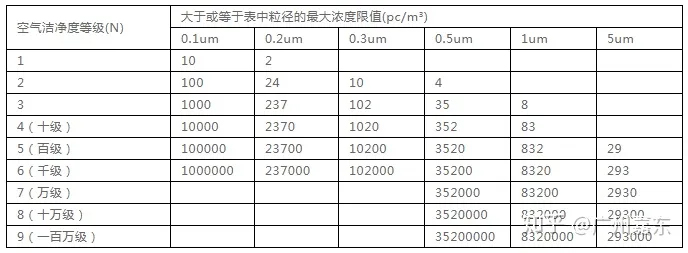

GB50073-2013 National Standard - Air Cleanliness Level

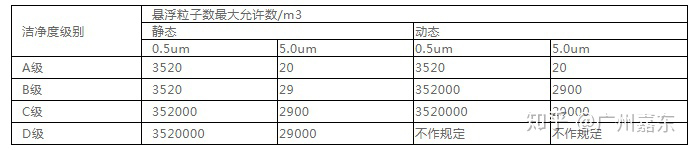

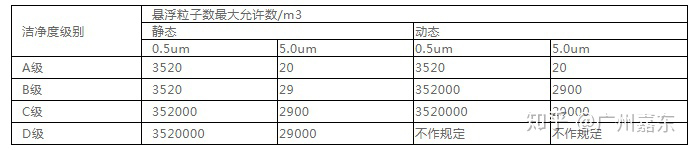

China GMP (revised in 2010)

New version of GMP Appendix 1 Sterile Drugs. Chapter 3. Article 9... The standards for airborne particles of each level in the clean area are as follows:

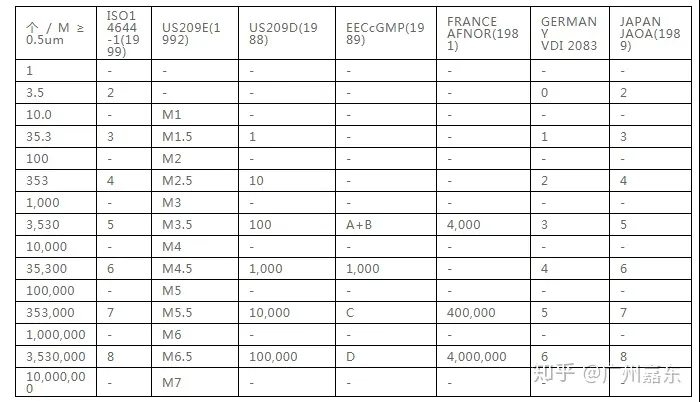

Approximate comparison table of cleanliness grades in various countries

Dust-free workshop (clean room) grade description:

The schema for class definitions is as follows:

Class X (at Y μm )

Where X is the grade of the clean room, such as 100 or 10000, etc., Y is the particle size such as 0.2μm, 0.5μm, etc., which can be selected multiple times. It means that the user stipulates that the particle content of the clean room must meet the limit of this level in these particle sizes. This can reduce disputes, here are a few examples:

Class1 (0.1μm, 0.2μm , 0.5μm)

Class 100(0.2μm, 0.5μm)

Class 100(0.1μm, 0.2μm, 0.5μm)

In Classes 100 (M3.5) and Greater (Class 100, 1000, 10000...), generally just look at one particle size. In Classes Less than 100 (M3.5) (Class 10, 1.... ), it generally depends on the particle size.

The second trick is to specify the status of the clean room, for example:

Class X (at Y μm ), At-rest

The supplier knows very well that the clean room must be accepted in the At-rest state.

The third technique is to customize the upper limit of particle concentration. Generally, the clean room is very clean when As-built, and it is not easy to test the particle control ability. At this time, you can simply lower the upper limit of acceptance, for example:

Class 10000 (0.3 μm <= 10000), As-built

Class 10000 (0.5 μm <= 1000), As-built

The purpose of this is to ensure that the clean room still has sufficient particle control capabilities when it is in the Operational state.

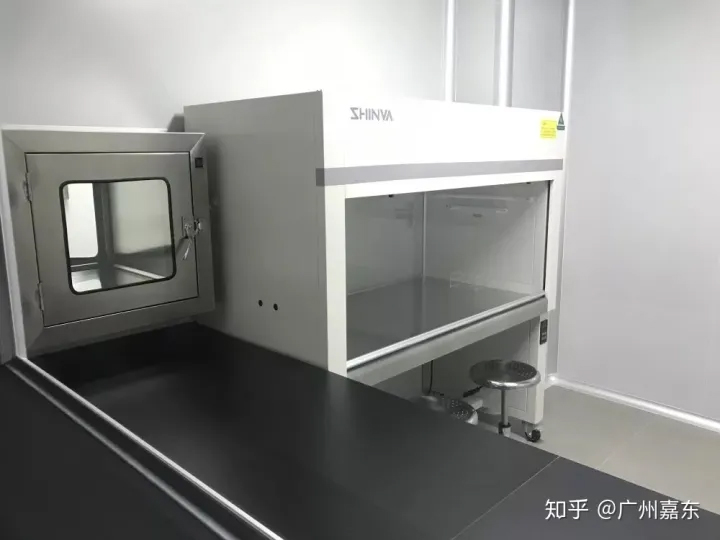

Clean Room Case Atlas:

1. Semiconductor industry:

Yellow light workshops are mostly built in Class 100 clean areas, and Class 1000 clean areas are also involved

2.Semiconductor clean room (raised floor) is often used in Class 100 and Class 1000 areas:

3.Conventional semiconductor clean room (clean area: class 10,000 to class 100,000):

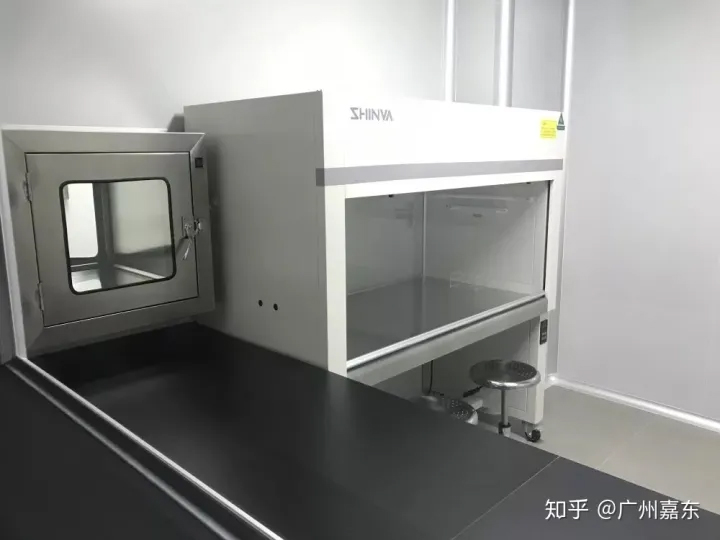

4.Conventional clean room:

Jiangsu Sunflower Machinery Co.,ltd offer Solution and Best Offer for Class 1000 Clean room of dust free work shop

Please feel free to contact us